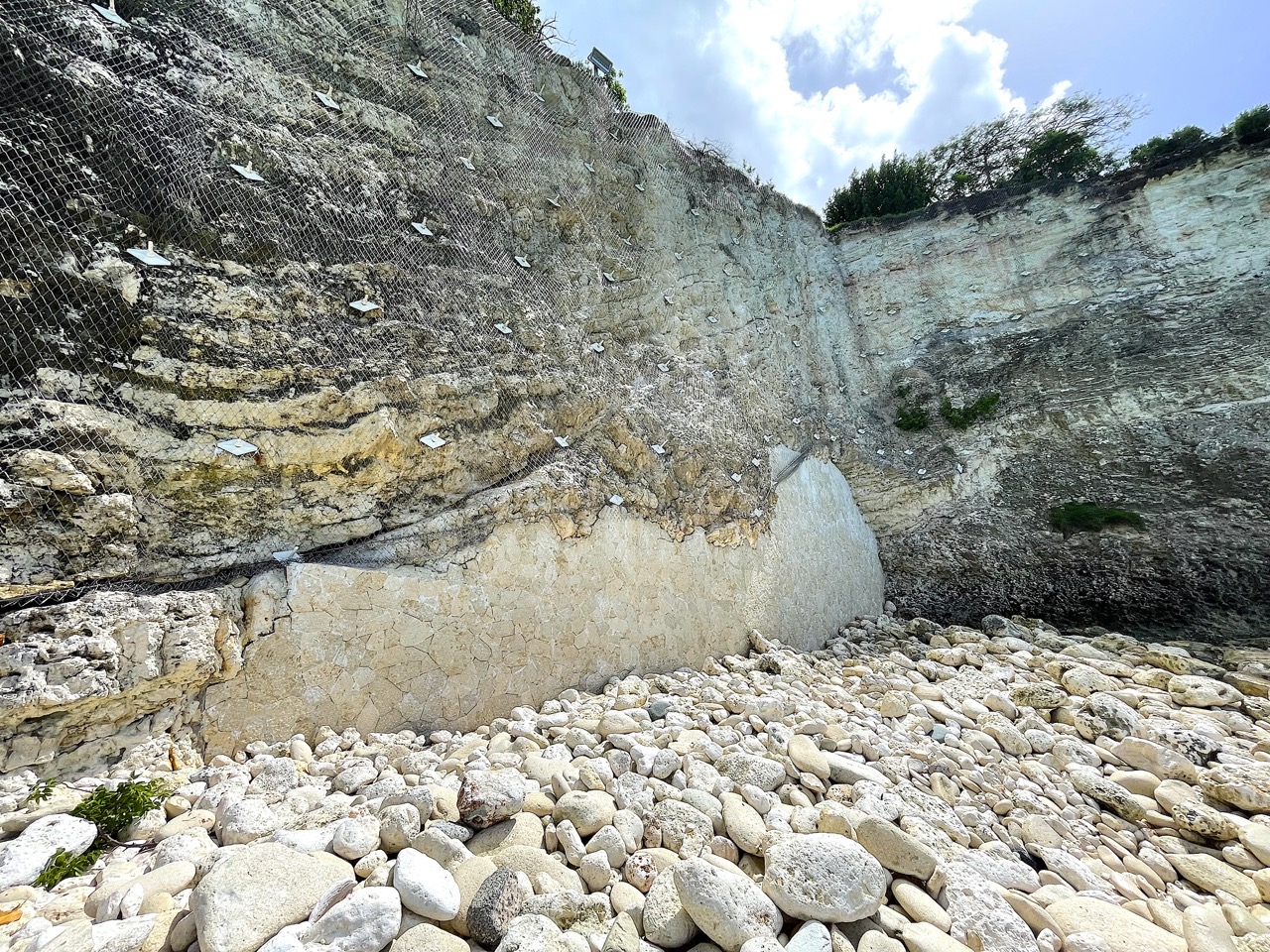

For certain configurations of undercut ground, overhangs or rock instabilities, it can prove necessary or interest to create an absolute foot stop via filling in a reinforced concrete support In this case, creating reinforced concrete buttresses / ‘buttons’ is a solution to the problem. The foot stop can be scaled in a way which takes into account the total support it needs to provide or it can be scaled to act along with the support of nailing higher up.

To create a good base for future works, the construction needs to confirm the ground’s bearing capacity and, where necessary, the works. This can be created by micropiles at the bedrock of the future stop.

Equally, it needs to be taken into account that the buttress / button will be constructed according to a chosen final geometry, realized by the use of a ‘tailormade’ casing. It is therefore indispensable to use during the construction horizontal nails / tie-rods. These have the double function of firstly allow the casing to be kept in place during pouring and secondly, offering a decisive way to keep good connections between the buttress / ground afterwards. (This means avoiding the effects of vertical surges transferred horizontally).

Significant numbers of buttresses can be constructed. However, it is crucial to maintain pouring heights over successive cuts, in line with the resistance of the casing used.

Different exterior claddings allow for the use of different amounts of concrete at different locations and in different contexts.

There are also options to:

- Leave the formwork rough

- Use plastering mortar / lime plaster

- Paint to the desired color

- Integrate facing with ‘real’ dressed stone

- Integrate facing via reconstituted facing stone

- Integrate facing stone via a metal trellis soldered with gabions